Laser hardening reinforces Engcon’s tiltrotators

Home »

An excavator needs to be flexible and technically advanced, as well as efficient, durable, and deliver consistent results. To satisfy these requirements, Engcon sought Permanova’s help to reinforce the material of its tiltrotators for its excavators by using laser hardening to harden various components. The result was fewer production stoppages for customers, and lower maintenance and servicing costs.

Engcon – the world’s leading supplier of tiltrotators

In 1985 Stig Engström introduced a tilting and rotating unit for excavators. He put his heart and soul into developing the product, and five years later he started Engcon, which today is the world’s leading supplier of tiltrotators. A tiltrotator can be described as the wrist of an excavator. It allows the bucket to rotate unimpeded on its axis as well as tilt 45 degrees for greater flexibility and efficiency. The tiltrotator means that the machine does not need to be moved to carry out advanced operations, and it can replace several other machines and result in less manual work.

Flexible and technically advanced in all types of excavation jobs

Engcon’s customers often work in different ways under different conditions. Some work to repair and expand infrastructure, while others undertake complex jobs in urban environments and in-house construction, which requires a high degree of flexibility due to the limited space. Consequently, they are looking for a premium product that is technically advanced and reliable. If Engcon’s products did not work, there would be a risk that its customers would perform inferior work or that the machinery would sit idle, which could result in substantial financial losses.

Laser hardening increases the productivity of excavators

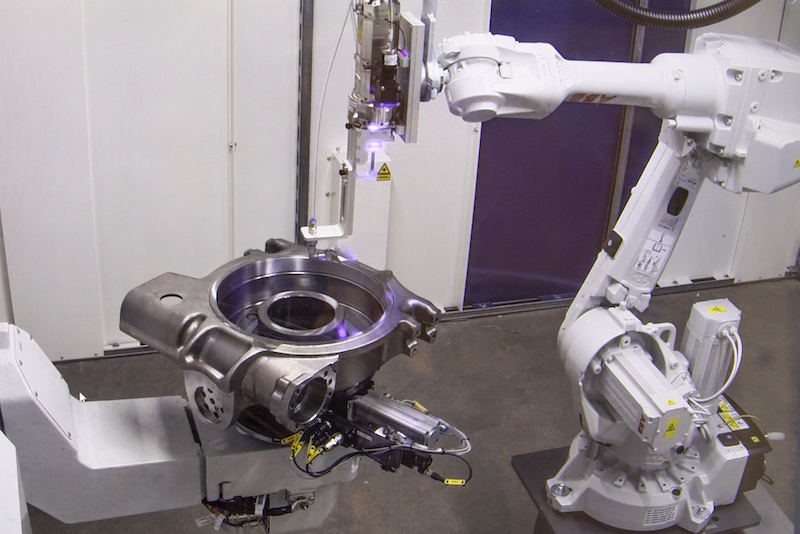

Engcon guarantees that its equipment is efficient and durable and that it provides stable and consistent results with a high level of productivity. In order to fulfil this promise, Engcon started using laser hardening in the manufacture of its tiltrotators.

“Our tiltrotators used to have wearing washers, which were really difficult to replace. We were looking for a more sustainable and cost-effective solution and for a method to strengthen the material on the most exposed surfaces. We started with selective laser hardening, which allows specific areas to be reinforced and reduces the need for post-processing, which is a huge advantage. That’s why laser hardening is the perfect solution for us,” says Emil Martinsson, machine operator at Engcon.

Engcon’s CEO, Krister Blomgren, continues:

“From a sustainability perspective, laser hardening has been a decisive factor. The biggest advantage of laser hardening is that it has reduced stoppages for our customers. Adding the process to the production chain was also relatively simple, which was important to us. Our goal was to reduce the risk of stoppages out in the field by strengthening the product. Now we don’t have to worry about having the problems we experienced before. Instead, we can say with confidence that we supply sustainable and reliable products.”

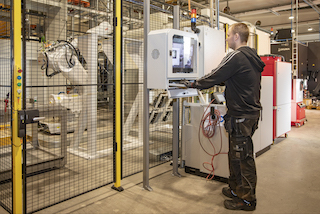

Automated production line with integrated hardening station

To further optimise its production, Engcon has subsequently added a robot to its laser hardening station and created an automated production line connecting both CNC machines and hardening stations. It is a 50-metre-long line, the purpose of which is to ensure the most consistent quality possible with as few staff as possible.

“This investment has enabled us to move production to our home, Strömsund, while safeguarding our workforce. The facility enables us to increase production, not just now but going forwards as well, as we have the ability to expand the system and double our production. One of Engcon’s primary goals is to double its sales within a few years. This investment, with the help of Permanova, makes this possible,” continues Emil.

“Laser hardening has been a success and the feedback from our customers is very good”

Engcon values long and close relationships with its partners.

“We want to feel confident that our suppliers and partners are giving us the latest and best that the market has to offer. We received offers from several parties, but we chose to work with Permanova because of the positive testimonials and recommendations. In addition, Permanova had previously supplied us with a similar station, which serves as a good reference point as we were very pleased with the work. We have enjoyed successful co-operation this time as well, with constructive and open dialogue throughout the project, where we worked together to solve any problems. We appreciate how Permanova has taken care of everything, as it’s easier and better to speak with the same party regarding all issues,” says Krister.

Emil agrees:

“When it comes to our suppliers, we value having good spare parts and that there’s always someone to get back to us and answer our questions. Permanova listened to our wishes and gave us the right information at the right time. We’ve also been given useful laser training by Permanova, at both a general and an in-depth level. Things worked so well with Permanova that we also asked them to help us with our automation solution. Our laser hardening has been a success and the feedback from our customers is very good.”

Permanova supplies robotic laser systems to the engineering industry

Permanova has been supplying laser processing tools and turnkey laser systems for more than thirty years. Our goal is to use our extensive technical knowledge and understanding of our customers’ needs to increase their productivity, product quality, and profitability. Our successful partnership with Engcon is a perfect example of this. We look forward to continuing to deliver the best possible production equipment to both existing and new customers in the future, as well as helping all those working in the engineering industry to rest easy.

I hope you enjoyed our article on Permanova and Engcon’s successful collaboration. If you have any questions, please don’t hesitate to contact me here. Take a look at our website for more information about Permanova and our solutions. And don’t forget to follow us on our sociala media channels!

Håkan Grubb | 2019-12-11